Posting some info about my test that helped me to best chose the right type of Carbon Fiber (CF) Cloth before starting starting my next CF project.

This CF experiment may help you:

1.) decide the type of CF weave you may want/need for your project

2.) decide how many layers of CF you many want/need for your project

3.) decide if you should vacuum bag (best) or just free lay up

4.) What resin you may want to chose

Internet videos abound telling us all about how to make things out of CF but they don't explain with much evidence how many layers you might need etc. If you google strength tests of CF layers you get crazy college papers barely written in English with all the big words and testing with units of measurement we've never heard of.

The other DIY guys who do have this and have more knowledge tend not to post it for fear of possibly creating knowledgeable competition.

Here I'll explain my data. I have another thread on how to make a high quality vacuum formed part out of carbon fiber for about $200. Vacuum bagging is the gold standard in getting the best/strongest end product, as opposed to "free lay up." Which is saturating the carbon fiber cloth the best and most even you can, without adding too much weight in excess resin; avoiding trapped air bubbles; getting the wetted out cloth to conform to the mold with gravity; on and on problems exist when you attempt to save time and effort by not using vacuum bagging. But I have pictures on it throughout my posts.

The test pieces I made were made using the professional industry standard of vacuum bagging, (but in my budget method

First thing to understand is there is some basic Carbon Fiber terminology to know before you buy. (not official, just my understanding):

1.) Never buy anything except the PAN manufacturing process (pitch process is less quality)

2.) Never buy CF that doesn't come on a roll... usually they come on rolls 50 inches wide and can be purchased by the yard... average price is $20-25 a yard that is 50 inches wide. Folded or remnant fabric left over from other people's projects is just a gamble.

3.) Pre-preg carbon fiber- is great. However it needs to be stored in a freezer because the resin pre-infused CF cloth will cure at room temperature eventually. (can be shipped to you at room temperature fine). ALSO, you need an oven big enough to bake your part in on a mold that can tolerate up to 500 degrees... take away: leave pre-preg CF for the pros that make lots of parts from expensive molds in big ovens.

4.) Weave- that is the orientation the groups of tiny strands of carbon fiber are arranged in when the manufacturer produces the "cloth" sheet of carbon fiber. Not all weaves are created equal (as you will find out in my research).

For example there is:

Twill: the classic "carbon fiber look"ie: 2x2 twill ... that means two bands of CF are patterned next to each other in the weave (I test 2x2 twill) (On the right in below pic)

Plain: that is the classic checker board looking weave... I also test this pattern. (On the left in below pic)

5.) Tow- that is talked about in "k" or thousands of units. I test 3k tow (2x2twill weave) CF that means there are 3,000 filament strands of CF in each thread group of CF that is being weaved. I also test in this experiment 12k tow (Plain weave) that means there are 12,000 filament strands of CF.... naturally the higher the tow, the thicker the fabric will be... but as you will find out in the testing... that doesn't mean it'll be stronger. See the picture of the ebay seller I bought from and the two fabrics I purchased from them:

6.) weight or GSM- it goes up with the higher the tow and better weave you buy. My 3k tow 2x2twill weave has a weight of 5.7oz per yard squared If I wanted to pay 30% more I could get an even tighter plain weave from Hexcel with the same 3k tow strands weaved in a product that is 5.8oz per yard squared. these two 3k products can be converted to a weight of about 200 Grams per Sq meter. The 12k product I was using is 300 GSM.

7.) Resin- is the liquid product you mix with the supplied hardener that cures (without the need for air, because it doesn't dry). Usually a 2:1 formula. Google it if you want to know more. The main thing you need to know is that you should buy epoxy resin

as opposed to cheaper polyester resin that is available at the hardware stores. Epoxy has superior strength, UV light protection, and clarity. You get what you pay for with resin so do your research. I used "Max Clear 1618 epoxy resin" I've also used "Max Clear High Performance epoxy resin"... but the 1618 is slightly more fluid and much better for vacuum bagging since it soaks into the CF cloth the best. "Max Clear HP" is best for those doing free lay up because its less likely to pool down to the bottom of the mold. More about it on the how to make a CF part thread.

I come to you with this experiment after completing Jobs like making my subframe, tail, retractable license plate, hinge, and cowel on my CBR 929 out of Carbon Fiber:

and making sets of heel guards based on the factor design for bikes like the 929/954, CBR 1000rr, Yamaha R1, and BMW S1000rr

front of mold with aluminum factor pieces resting on top

Back of mold

|

| Yamaha R1 carbon fiber heel guards for 2009 |

|

| CBR 1000rr heel guards, not much different than 929 and 954s |

basic experiments like this:

Trial and error to find best way to make heel guards out of a reusable mold. Fifth time worked

That Vaseline is not a good mold release

Finding the best way to make a mold:

Plus lots of messing around with free lay up etc wasting CF and epoxy to self teach myself:

Lastly: trying to make a mold out of clay and other material:

1.) Clay was too moist when molding the clay so it dried incorrectly and cracked (turns out you don't have to let the clay dry)2.) tried to salvage job 1 and found clay was too inconsistent to proceed to casting

3, 4, 5) was a week long pain staking attempts to use foam and it turned out to be FAR more time consuming than working with clay

6.) Complete restart, made this up in short three hours... now to casting

7.) LOL, spraying some "great stuff" foam into a mold was a disaster

Start of Carbon fiber layer testing:

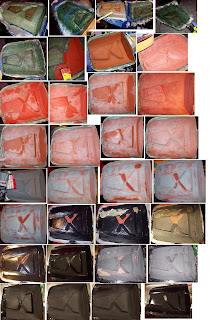

I planned to make varying layers of carbon fiber with different weaves and to make 3 of each type to get an accurate average of strength. To create 3 of each test piece of different layers and components that looks like these:

I had to create a mold to form these pieces. as you can tell from the three humps it created three rows of each test sample to get me accurate averages on weight and strength of the different types of carbon fiber weaves and layers:

I used paper to determine the size of each piece of carbon fiber that I needed for each test piece. This is the heavier 12K tow... I also used about this much of the 3k tow twill too. It's important to use a substitute like paper or an old bed sheet as your mock piece of CF when determining the size of the piece you need. That's because if you handle carbon fiber it EASILY looses it's weave causing the weave to separate and weakening your end product introducing peaks and valleys called "crimp." According to Polymercompositesinc: "crimp, significantly reduces accumulation of matrix at the interlacing points and thereby the dead weight of the final composite material. This not only reduces the weight of the final composite material product but also eliminates the print-through defects associated with post curing of the undesired matrix accumulation."

You might notice that I used a bead of Elmer's glue on the edge if the CF and let it dry before rolling it back on the roll after I lasted used it. That way to prevent the weave from distorting. I don't do that anymore, instead I just cut out the surrounding remnants in small enough pieces that they can fit into a zip lock bag and then I can use in small parts.

Here's what the mold looked like with the CF sitting on it dry... on the far right ended up to be a failed attempt to test 2 and 3 layers of fiberglass... it was so weak it couldn't even hold up the .07lbs of empty water jugs used to inflict measurable force on the pieces!

As you can see the largest pieces of carbon fiber were laid across first creating the base for other layers with that weave in the final piece... I tested two main different weaves 2x2 3k tow twill on the left and 12k tow plain weave on the right. both samples got one more layer thick in each step as you might be able to tell... if this is all uninteresting or confusing just skip to the end of the study to get the data on strength.

Like most people's projects with carbon fiber, they will cover the under layers with a top layer of the "better looking" 2x2 twill. So I covered the sample with a single layer of it:

As you can tell the difference between the layers of CF laying dry on the mold (or even if they were wetted out with resin) that you can't distinguish the details of the mold (above) to the picture of the wetted out fabric in the vacuum bag (below).

Note: I will explain the whole process on how to vacuum bag a piece this size or bigger for about $200 total in a different thread. So don't worry that you may be missing out on the process. Again, this is just the process and results of my testing. Rest assured the layers of CF were each wetted out with epoxy and layers in typical fashion as the how to videos... the only deviation I have from those videos is the money saving alternative materials and tools involved with getting the high quality end result

After a good 10 hours under full vacuum with my little 3cfm pump from ebay (more on that in other thread)... the piece cured perfectly. Notice the white fiberglass on the right of the piece was contaminated with strands of CF... despite this the 2 and 3 layered test pieces of fiberglass still couldn't provide accurate strength data because they couldn't even hold the .07lbs worth of empty scale material! So needless to say fiberglass is weak unless bulked up with over a half a dozen layers... at that point a part of equal strength to carbon fiber piece would weigh multiple times more.

To maximize strength I let the part cure for a week at room temp before cutting the test pieces apart and doing the experiment. As you saw each row of a certain thickness and weave had three pieces out of it. Here they are pictured separated. The Abreviations are:

N: "normal" carbon fiber... meaning the 3k 2x2 twill weave

W: "wide" carbon fiber.... meaning the 12K plain weave

F: "fiberglass" simple hardware store plain weave fiberglass for which no useful data was obtained because it was too weak to hold the scale equipment.

2N: two layers of 2x2 twill weave carbon fiber. (The three specimens differentiated with an a,b, and c: 2N(a), 2N(b), 2N(c))

3N: three layers of 2x2 twill weave carbon fiber. (3na, 3nb, 3nc)

4N: four layers of 2x2 twill weave carbon fiber. (4na, 4nb, 4nc)

5N: five layers of 2x2 twill weave carbon fiber. (5na, 5nb, 5nc)

6N: six layers of 2x2 twill weave carbon fiber. (6na, 6nb, 6nc)

1N2W: one layer of 2x2 twill weave (top layer) and two layers of 12K plain weave (1n2wa, 1n2wb, 1n2wc)

1N3W: one layer of 2x2 twill weave and three layers of 12K plain weave (1n3wa, 1n3wb, 1n3wc)

1N4W: one layer of 2x2 twill weave and four layers of 12K plain weave (1n4wa, 1n4wb, 1n4wc)

1N5W: one layer of 2x2 twill weave and five layers of 12K plain weave (1n5wa, 1n5wb, 1n5wc)

1N6W: one layer of 2x2 twill weave and six layers of 12K plain weave (1n6wa, 1n6wb, 1n6wc)

the "a", "b", and "c" weren't on the specimens yet in this pic

Here's a pic of them after I power sanded the sides down so each piece had the same measured dimensions so that if laid flat they'd be 90mmX35mm.

view of an example of one of each test piece as well as a sample of the two types of CF that I used in the testing

Here's a pic of what the stress test entailed. It was simply clamping the "L" shaped piece of CF with a drilled hole through each piece at the exact same distance from the bend to hook the scale on.

I'd fill the first jug with water through a funnel with a 1/2" tube outlet to standardize the speed at which the jugs were filled.

The first jug would be filled until the first sound of a "crack" was heard (unmistakable) That means the piece is forever compromised and wakened... unlike metal parts that when hit merely get dented or bent slightly, fiber parts will fracture and never tolerate a second blow... ie: hit your crappy car that won't start with a metal bat it'll still probably be okay... do that with a carbon fiber or fiberglass bat and you'd be holding the equivalent of a wet noodle by the third hit.

Once the first "crack" was heard then the second jug would immediately began being filled with the same funnel slowly until the part would "snap" and critically fail.

Here's an impressive pic of 6Nb carbon fiber holding just shy of 20lbs of water! to think... just a 1.5inch wide and 2.09mm thick piece of anything could hold that much weight!

Here's a pic of the fractured 6NB with all the weight it held before finally fracturing... 19.6lbs! Also pictured in my hand is 6NC as an example of what the thickness of the copy of the part looks like.

After a couple hours the pieces were all tested and recorded:

Here's all the data written out in a graph for each A, B, and C part of different thickness and weave... the bottom row is the average of each sample types three copies specific parameters:

Thickness: - measured in mm. is the average thickness of each part. Average because I took four measurements from all the different sides of each piece to account for any inconsistencies in each piece... there really wasn't significantly much as I found out later by the average trend increase in thickness began to be predictable.

Weight: measured in ounces of each piece

Strength- "crack": measured in lbs. The first jug would be filled until the first sound of a "crack" was heard (unmistakable) That means the piece is forever compromised and weakened... unlike metal parts that when hit merely get dented or bent slightly, fiber parts will fracture and never tolerate a second blow... ie: hit your crappy car that won't start with a metal bat it'll still probably be okay... do that with a carbon fiber or fiberglass bat and you'd be holding the equivalent of a wet noodle by the third hit.

Strength- "snap": second jug would immediately began being filled with the same funnel slowly until the part would "snap" and critically fail. the two numbers per box for this recording is simply: the top number in black is the wt of the second jug... the bottom second number in blue pen is simply the adding "crack" and "snap" weights together.

How the results can help you decide how many layers to make whatever you are making out of carbon fiber:

This is most evident when you hold a large sample up to light.

Here's a piece made up of 1 layer of 3k 2x2twill and 2 alternating layers of 12k plain weave (1n2w) plus a fourth layer made of one small piece of 12k weave toward the top of it that folded in on it's self... for no reason. It was vacuum formed. Smooth to the touch, just a little uneven because of the vacuum tube that pressed into the piece as it cured under negative pressure (it was another experiment piece). The other side has the 2x2 twill:

Same piece held up to 100 watt light bulbs and even the top that had the fourth layer had a couple pin holes for light to shine through. These "pin holes" are merely areas without CF and only resin, not palpable to the touch since the voids are filled with clear resin. And the holes aren't visible when held over anything but light (ie: a white piece of paper)... so a part like this may be cosmetically good since it is sturdy as 3 layers of carbon fiber vacuum bagged formed together would be. However, it's not structurally strong as three layers of 3K 2x2 twill.

The most important factor to take away:

1.) if making a structural carbon fiber part use a CF cloth with the tightest weave.

Not saying 12k plain weave is bad... but if you do decide to use it make sure it doesn't have large gaps in the weave.

I hope this write up of my experiment will help you on your project when your trying to decide what carbon fiber cloth and resin to buy. As well as trying to decide how many layers you might need.

If you have any questions about this experiment let me know here or on our page www.fb.com/929and954

-Matt Behning

HOW TO: Vacuum formed Carbon Fiber Part for $200HOW TO: CBR 929 Factory Pro Shift Kit Install w/ Clutch and Tranny Assessment

HOW TO: Rebuild a Motorcycle TransmissionHOW TO: Plastic weld and paint prep